I-17 Improvement Project using foam glass aggregate as a new innovative construction material

I-17 Improvement Project using foam glass aggregate as a new innovative construction material

If you’ve driven along the I-17 Improvement Project corridor between Anthem Way and Sunset Point, you may have seen many large white bags in the middle of all the ongoing construction work.

The bags are filled with Ultra-Lightweight Foam Glass Aggregate. This unique material, which is made from 100 percent recycled glass, is being used at 19 locations throughout the project corridor. This recent video gives you an up-close look at foam glass and how it’s incorporated into the I-17 Improvement Project.

The bags are filled with Ultra-Lightweight Foam Glass Aggregate. This unique material, which is made from 100 percent recycled glass, is being used at 19 locations throughout the project corridor. This recent video gives you an up-close look at foam glass and how it’s incorporated into the I-17 Improvement Project.

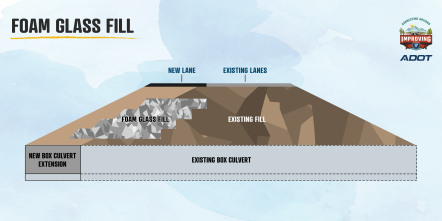

Because this is a strong, lightweight and waterproof material, the foam glass will be used primarily to help strengthen the existing box culverts, which are concrete structures designed to channel water. The culverts were originally designed to withstand the weight of a two-lane roadway. The foam glass is used as fill material to support the weight of the additional lanes along the 23-mile stretch of I-17 that will include both widening and flex lanes.

The foam glass is manufactured in Florida and this is the first time it’s being used in Arizona. Foam glass is made by crushing recycled glass into a powder and mixing it with a foaming agent. The mixed powder is then sent through a kiln and softened. During this process, the foaming agent creates bubbles within the softened glass, which in turn creates the foam glass, an inert, non-leaching, rot-resistant, non-flammable, durable construction material.

Foam glass is not only an innovative material for construction, it’s sustainable and environmentally responsible as well.

To learn more about the I-17 Improvement Project, visit Improvingi17.com.