Building a Freeway: Soffit Fills and Waste Slabs

Building a Freeway: Soffit Fills and Waste Slabs

When you’re building bridges, there’s more than one way to get the job done...

We told you a few months ago about a method that utilizes false work and sand jacks. Today, we’re going to fill you in on a different approach … the key terms to remember are soffit fills and waste slabs.

If you recall, false work is what secures the bridge structure as it is being built and until it can stand on its own.

A soffit fill (basically a big pile of dirt) acts much in the same way.

After the bridge piers and abutments are cast, the area in between is filled with dirt. That dirt is piled right up to the height of where the bridge deck eventually will sit … this soffit fill will act as the false work, providing a strong foundation to build the bridge on top of.

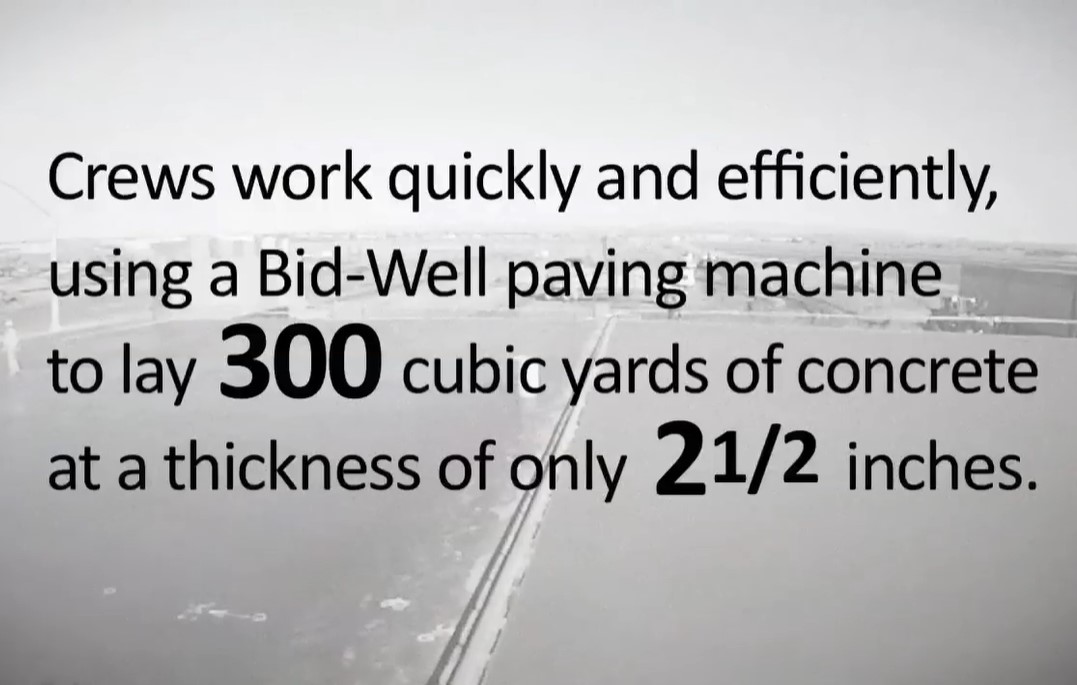

With the dirt in place, a thin concrete slab – the waste slab – is poured on top (see video below). The flat, smooth surface is what crews will build upon, but the waste slab won’t be a part of the finished bridge. No, the job of a waste slab is to simply give crews a form on which to pour more concrete.

Maybe a little analogy right about now might help you get the picture. Take a second and think about making a pie (trust us!).

Your counter top is acting as the soffit fill – giving you a surface to work on. Now imagine your pie pan as the waste slab – it’s giving you a form to shape your crust, but after the pie comes out of the oven, you’re not going to need the pan … your piece of pie will stand on its own!

OK, with us still? You’ve got your counter top (soffit fill) and your pie pan (waste slab), but before you place the pie crust you want to make sure it won’t stick to the pan … maybe you’ll use some non-stick cooking spray?

That’s kind of what crews use out in the field. They spray a thin wax coating over the waste slab so when they pour the concrete for the actual bridge structure on top, it won’t stick. Because remember the waste slab is just that – waste. It’s only there to temporarily provide a surface for the building of the bridge, but eventually it will be removed along with the soffit fill.

From there, crews complete a number of additional steps...

Keeping with our pie analogy – there’s “filling” involved with some bridges. In the case of the bridge being built at the Loop 303 and Waddell Road, the crews are actually building “lost decks,” so named because the materials ADOT uses in the framework will remain inside the bridge structure for the lifespan of the bridge.

These “lost decks” are inside the bridge and give it strength, but also allow for some open space, because a bridge of this size made entirely of concrete would be too heavy.

After the filling is inside, all that’s left to do is place the top crust, a.k.a. the top deck, which is what motorists will eventually drive on.

Crews will then bring in heavy-duty equipment to remove the soffit fill and the waste slab, but we’re going to save that for another blog post … so stay tuned!