Diamond Grinding Pavement Treatment

Diamond Grinding Pavement Treatment

Contents

What is Diamond Grinding?

Diamond Grinding is a technique for preserving and rehabilitating the concrete pavement surface of a highway, which also helps reduce tire noise.

Benefits of Diamond Grinding

Diamond grinding concrete pavement has several benefits compared to a rubberized asphalt overlay. While both rubberized asphalt and diamond grinding provide noise reduction benefits, diamond grinding is a more sustainable and cost-effective solution. A diamond ground surface has a service life of approximately 30 years, compared to a service life of rubberized asphalt of 10-15 years, and also requires less ongoing maintenance. A diamond ground freeway surface stays consistent over time, whereas rubberized asphalt wears down, creating an uneven ride and increased noise levels. Noise levels have not been shown to increase over time on freeways treated with diamond grinding.

Diamond Grinding Pilot Program

The pilot program was initiated in 2020 by the Maricopa Association of Governments (MAG), in partnership with ADOT, to explore the use of concrete surface treatments as a more cost-effective, long-term alternative to replacing the aged rubberized asphalt overlay on much of the Regional Freeway System in Maricopa County, which had exceeded its useful life. The cost associated with replacing and maintaining rubberized asphalt was estimated at $1 billion between 2020 and 2029.

Following the three-year pilot program, in October 2023 the diamond grinding program was expanded for use on all feasible projects in the Regional Freeway System in Maricopa County by the Maricopa Association of Governments (MAG) Regional Council.

The findings of the pilot program determined that diamond grinding outperforms rubberized asphalt in nearly all criteria, including long-term ride quality and life-cycle cost, while reducing traffic noise.

Diamond grinding is projected to save millions of dollars in pavement-rehabilitation costs and free up funding for future freeway improvements.

The long-term performance of diamond grinding on Valley Freeways will continue to be assessed as part of the expansion of the program.

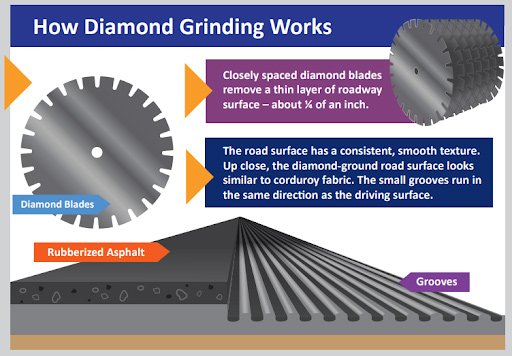

Closely spaced diamond blades remove about ¼ of an inch of the roadway surface, providing a consistent and smooth texture that resembles corduroy fabric. The small groves run in the same direction as the driving surface.

Where will diamond grinding be used?

Diamond grinding will be used on new pavement rehabilitation projects where feasible. Diamond grinding requires a concrete base surface and can’t be used on freeways in Maricopa County that have an asphalt base, such as Interstate 10 between SR 85 and Verrado Way, the Loop 202 South Mountain Freeway and I-17 north of Anthem Way. Other factors, such as the condition of the existing concrete, go into the determination of whether diamond grinding or rubberized asphalt is most appropriate.

Questions or comments?

ADOT welcomes your questions or comments about diamond grinding:

- Phone: ADOT Project Information Line at 855.712.8530

- Email: [email protected]

- Mail: ADOT Communications, 1655 W. Jackson Street, MD 126F, Phoenix, AZ 85007