From the Archives: The science of transportation

From the Archives: The science of transportation

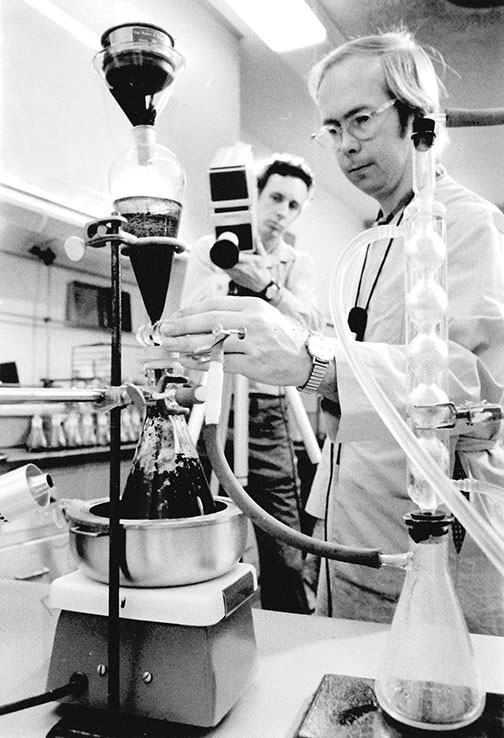

Taken in 1974, this photo shows a lab technician performing the vacuum recovery of asphalt emulsion residue.

We’ve told you before that highway construction isn’t just big machinery, heavy-duty vehicles, massive structures and materials by the ton. There’s actually a whole lot of work that happens off project sites and inside a lab.

That was clearly true back in 1974 when this photograph was taken.

Since we weren’t exactly sure of what’s happening in the picture, we reached out to ADOT’s current Asphalt Lab supervisor, who tells us the procedure being performed more than 40 years ago, known as the vacuum recovery of asphalt emulsion residue, is still done today.

He said the method makes it possible to separate the asphalt out of an asphalt emulsion.

Before we get to why that’s valuable, let us first explain that an asphalt emulsion is just a mixture of asphalt, water and a soap solution (water and asphalt don’t mix, so the soap acts as an emulsifier that helps bind everything together).

The emulsion is a sort of liquid asphalt that’s used for many road surface treatments like slurry seal coats, which help fill cracks and minor depressions in older asphalt concrete pavement. Asphalt emulsions can also be used for tack coats, which are what’s sprayed on the road before crews place the asphaltic concrete pavement, and for chip sealing.

Once separated from the water/soap mixture, the asphalt is ready for testing.

Many tests can be conducted on asphalt as a project is being constructed (to ensure it meets specifications) or as a part of research when ADOT is evaluating/designing new projects.

For example, different types of asphalt perform better at certain temperatures, so ADOT’s Asphalt Lab tests asphalt to make sure it will perform at the highest and lowest temperature that it is graded for. Another test measures the asphalt’s elastic properties, while another one “cooks” the asphalt overnight in a pressurized oven to artificially age the asphalt by five years.

“That way, we can predict how the asphalt’s properties will change and how well it will perform in five years,” said Asphalt Lab Supervisor Dan Anderson.

So back to that photograph…

Anderson explains that the lab technician in the picture would have first added isopropyl alcohol to the emulsion. That quickly separates out most of the liquid and what you end up with is a “lump of asphalt that looks like Play-Doh or clay,” Anderson said.

From there, other steps for the procedure include rinsing the asphalt and putting it into a flask that’s attached to a vacuum. A hotplate heats the asphalt in order to slowly boil off the rest of the water, which is then suctioned off by the vacuum.

When it’s all done – in roughly 45 minutes – you’re left with just the asphalt!

While ADOT lab techniques have certainly evolved with the advancement of technology, vacuum recovery remains an effective and widely used procedure, however, it’s not the only way to remove moisture from an asphalt emulsion – ADOT’s Asphalt Lab has a few different options (but we’ll save those for another blog post!).

It’s safe to say things have changed since 1912 when the Arizona Highway Department was first established. But you don’t just have to take our word … we’ve got plenty of pictures to prove it. We combed through our archives and decided to periodically post these photos from the past in a blog series we’re calling, “From the ADOT Archives.”