How a bridge comes to life

How a bridge comes to life

A bridge is often an awesome sight to behold: Thick pillars, massive abutments, maybe lots of shiny steel tubing soaring into the sky above a canyon. Or, it could be as simple as a concrete structure crossing a small wash (like the Lowell Arch Bridge near Bisbee).

A bridge is often an awesome sight to behold: Thick pillars, massive abutments, maybe lots of shiny steel tubing soaring into the sky above a canyon. Or, it could be as simple as a concrete structure crossing a small wash (like the Lowell Arch Bridge near Bisbee).

You may have wondered, if you've passed by or driven on one recently: How did this thing get designed and built?

Wonder no more: Bill Downes, an ADOT design engineer, is here to help explain the process. He says a bridge design engineer must consider three very important points:

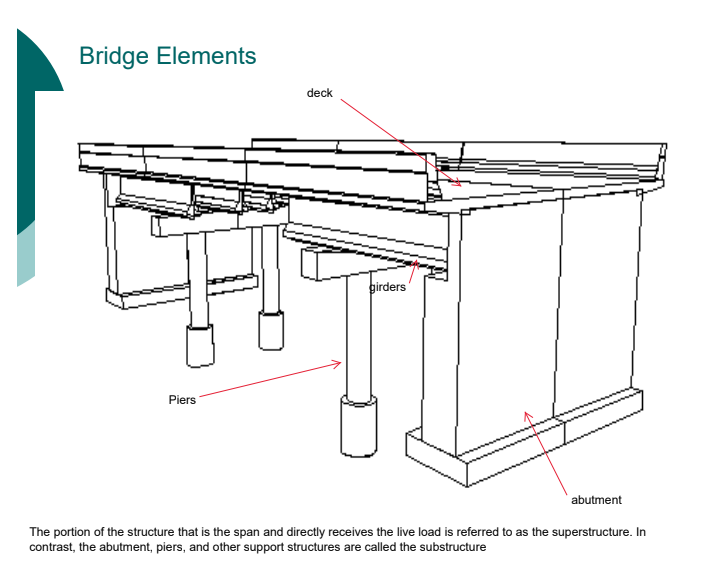

- Geometry: "How long does the bridge need to be, what does it go over and how high is it," said Downes. "The bridge must be high enough to allow traffic or flood water to pass under it."

- The number of spans: "Essentially how many piers will be needed. Where can piers be placed is also a major factor in this decision. You cannot place piers in a roadway. Where is the roadway below the bridge, and where will it be in the future?"

- Traffic: "This is not much of a problem on a new bridge on a new roadway, but it is very important on a bridge replacement. Can the new bridge be built next to the existing bridge and the roadway moved over? Can the road be closed/detoured during construction? Often traffic must continue even while trying to build a new bridge."

In addition to all of these, Downes says, the engineer must also take into account utilities near the proposed site; how and where construction crews will access the site and store their equipment; and whether accelerated bridge construction (ABC) methods can be used.

"Although ABC reduces traffic disruptions, they generally cost more and require special planning," he says.

The topography and soil of the proposed bridge site are also important.

"What type of soil is in the area, and what types of foundations can hold up the bridge. Can shallow foundations like a spread footing be used, or are deep foundations such as drilled shafts required?"

Then comes the review.

"As each item is looked at, it may change the choices made earlier," says Downes. "For example, the ability to ship girders to the worksite may change how many piers you will need to have."

After all the data gathering and review, it's time to start designing!

"This is the point where we start the math to determine how strong each bridge element needs to be," he says.

Although no one can predict future traffic patterns, engineers must allow for that, too.

"Bridges historically were designed to last 50 years," he says. "Generally we now design for a 75-year life and many will be expected to continue to carry traffic for over 100 years with only little maintenance or rehabilitation."

Once the design is completed and approved, Downes says, plans must be made for contractors; and once a contractor is chosen, the bridge design engineer will need to work with the contractor throughout the construction process.

The most important point of all?

"Although bridges are beautiful things they don’t exist in isolation," Downes says. "Building a bridge cannot be accomplished without a great deal of coordination and work with roadway, geotechnical, traffic, district, right-of-way, utility, environmental, material, drainage and other engineers."