Weathering machine simulates heat and rain for ADOT testing

Weathering machine simulates heat and rain for ADOT testing

The Accelerated Weathering Tester is used to analyze how well paint will perform on ADOT projects.

Ultraviolet lamps inside the device give off destructive UVB rays to simulate heat and sunlight (inset).

Watching paint dry is the very definition of boring, but observing paint to see how it’ll hold up against the elements can really get interesting…

Not convinced?

Well, did we mention the process involves a weather simulating device that can conjure up rain, humidity and harsh sunlight with the push of a button?

It’s actually called an Accelerated Weathering Tester and it’s used by ADOT’s Materials Testing team to analyze how well paint will perform on ADOT projects, come rain or shine.

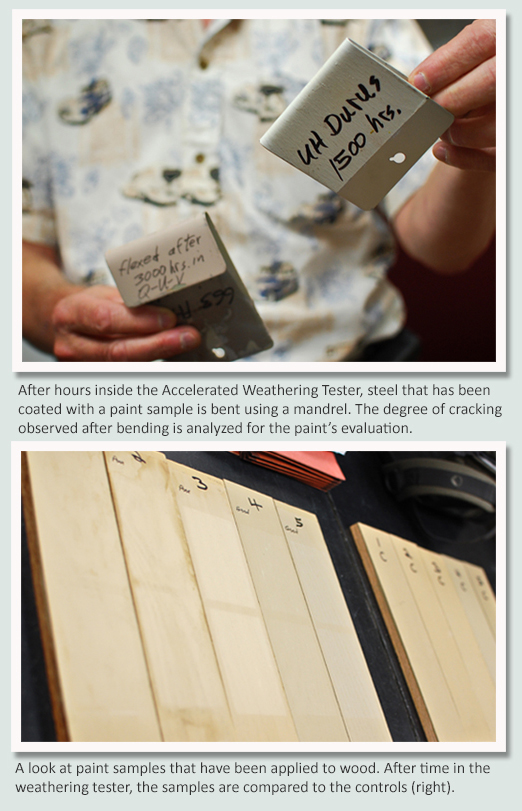

(top) After hours inside the Accelerated Weathering Tester, steel that has been coated with a paint sample is bent using a mandrel. The degree of cracking observed after bending is analyzed for the paint's evaluation.

(bottom) A look at paint samples that have been applied to wood. After time in the weather tester, the samples are compared to the controls.

After many weeks in the tester, ADOT gets an idea of what the paint will look like years from now.

“We program it to simulate different weather phenomena,” explains ADOT Chemist Jeff Faulkner, adding that the ultra violet lamps inside the device give off destructive UVB rays – the same type that are responsible for sunburns.

The machine also has nozzles inside that spray water to simulate rain. With various combinations of “sunlight” and “rain,” ADOT chemists like Faulkner can program many different weather conditions and humidity levels.

Faulkner and his team fire up the Accelerated Weathering Tester when a paint manufacturer wants to have one of their products added to the Approved Products List (the list is updated regularly and includes products that have been evaluated and found acceptable by ADOT – we blogged about it in 2011).

After the manufacturer sends over a sample of paint to be tested for inclusion in the Approved Products List (APL), ADOT chemists will apply a coat of it onto a thin panel of either steel, wood or masonry block, depending on the type of paint.

Once the paint dries, the sample goes into the Accelerated Weathering Tester for up to 2,000 hours of exposure. The paint gets rained on, heated up and is subject to humidity.

After the time is up, the ADOT chemists will check the sample for cracking, blistering, corrosion, adhesion, chalking and flexibility.*

Besides observing how well the paint held up, the chemists will check the paint against a control sample, which is prepared in exactly the same manner as the test sample, but isn’t exposed to anything – not even the fluorescent lights in the lab.

From there, a results report is prepared and is sent to ADOT’s Materials Product Evaluation Committee. The committee uses the test results when considering whether to allow a paint product onto the APL. If accepted, that paint product can be used on ADOT projects.

* How can paint be flexible, you wonder? This criteria has to do with paint that’s been tested on steel. After it’s time in the weather simulating machine, the sample is bent using a mandrel. The degree of cracking observed after bending is used for the rating.