Throwback Thursday: Testing pavement friction in 1977

Throwback Thursday: Testing pavement friction in 1977

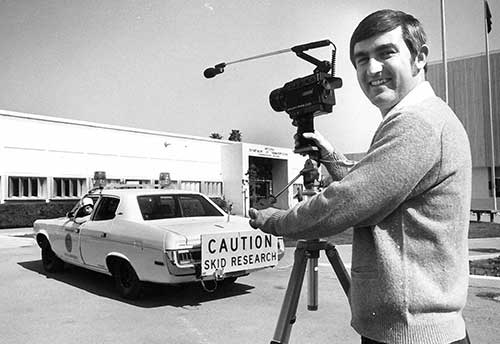

This photo appeared in the April 1977 issue of NewsBeat, a publication that served up agency news to ADOT employees for decades. Printed alongside of it was this caption:

John Burns of Materials Services prepares to shoot a scene with a Super-8 mm camera for a 25-minute sound film he’s producing on how differential pavement friction affects skidding vehicles. Burns was a chief investigator on research. FHWA (the Federal Highway Administration) is funding the movie to be shown in other states.

That’s not a whole lot of information to work with, and we have so many unanswered questions. Good thing David Allocco, a.k.a. the guy in the driver’s seat, agreed to share some additional details.

Allocco, who started with ADOT in March 1973, works today in the Bridge Group’s Geotechnical Section as a materials source engineer. While his job no longer involves measuring pavement surface friction, he distinctly remembers driving that vehicle.

Used to test the wet friction characteristics of a roadway, the car had special features, including special bald skid-testing tires, a roll bar and a harness. The safety equipment was necessary because of the testing methods...

“We’d have a water truck that would wet down the road,” Allocco said. “Then, I’d get the car up to speed, put it in neutral and then you’d have to slam on the brakes as hard as you could with both feet.”

Engineers would measure how far the car skidded and would use the distance to determine a coefficient of friction, Allocco said.

While the vehicle was typically used for research and to test out small sections of various roadways (another device known as a Mu-meter was used to test longer stretches of pavement), Allocco remembers a unique request that came from the Tucson International Airport.

“The Air Force had been doing touch-and-go landing exercises at the airport, and they wanted us to test to see if the friction was affected,” said Allocco, adding that he skidded 655 feet and ended up farther than expected, past the wet part of the pavement.

“That was the most exciting time I ever drove it,” he said.

Today, ADOT still tests pavement friction, but the methods have evolved.

Now something called a Dynatest Highway Friction Tester is used, said Pavement Condition and Evaluation Manager Kevin Robertson. It’s a truck with a 300-gallon water tank and an extra wheel that, when a test is activated, mimics what vehicles experience when braking on the wet road.

“It tells us the macrotexture of the road,” said Robertson, adding that the sophisticated onboard technology calculates a friction number ranging from 0 to 100, giving engineers the data they need to make decisions about pavement maintenance.

“When it comes to the ability to test pavement friction, we have the most advanced and safest machine available to do that,” Robertson said.

It’s safe to say things have changed since 1912 when the Arizona Highway Department was first established. But you don’t just have to take our word … we’ve got plenty of pictures to prove it. We combed through our archives and decided to periodically post these photos from the past in a blog series we’re calling, “From the ADOT Archives.”